SERVICES

HDD Drilling

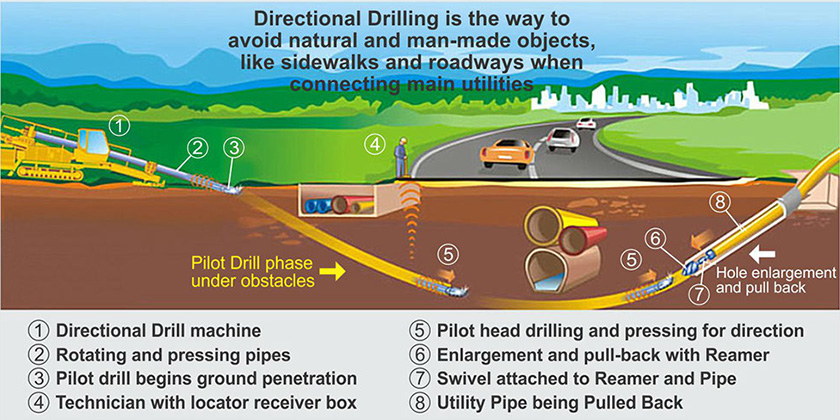

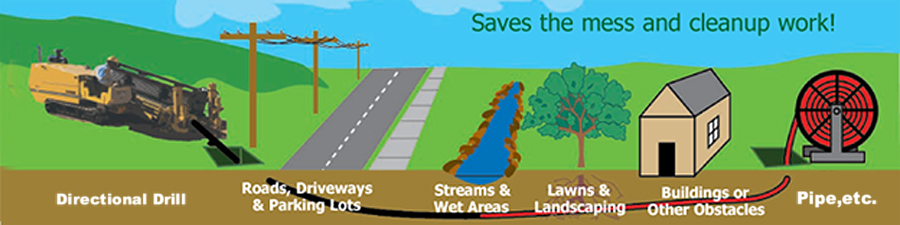

Horizontal Directional Drilling (HDD) is a construction technique whereby a tunnel is drilled under a waterway or other designated area, and a pipeline or other utility is pulled through the drilled underground tunnel.

Different Types of Directional Drilling

- Road crossing drilling

- Gradient Stormwater pipes

- Optic Fibre installations

- Construction Projects

Advantages of Directional Drilling

- No open trenches or damages / erosion to a variety of surfaces

- Small entry and exit point

- Installation at highly congested areas / residential areas with minimal damage to surrounding areas

- Little to no impact on traffic flow

- Little to no reinstatements to brick surfaces, tar, concrete or any gardens beddings

- Larger distance Capabilities

Scanning

RD1100 Utility Ground Penetrating Radar

The RD1100™ Ground Penetrating Radar detects both conductive and non-conductive underground utilities using wide-band radar technology and features internal GPS, on-board Wi-Fi, and a high-resolution touch screen.

Radiodetection’s RD1100 provides high-performance subsurface imaging for buried utilities in a rugged and competitively priced GPR system. Designed for the utility industry, the RD1100 features a wide-band sensor capable of detecting plastic and ceramic utilities at depths of up to 8m / 27’ deep.

Its high-resolution touch screen display adds to its ease of use, including the ability to draw arrows directly on the screen to highlight subsurface features of interest.

Screenshots are taken with a single button press and saved to internal memory as JPGs. These can be exported later to a USB memory stick or emailed by connecting to a Wi-Fi network or by using a cell phone as a hotspot. Instant information, higher productivity!

GPS positioning is captured alongside the Line View data for integrating into geo-referencing packages.

Pipe Cracking / Bursting

Pipe cracking is a very effective trench less service that is used to replace underground water and sewer pipes.

Instead of digging up the old or damaged pipes, this trench less method makes use of a “bursting head” that is pushed into and through the existing pipe. This head fractures the old pipe and sends the remaining materials and fragments into the surrounding soil area. The new pipe is immediately pulled into place, with no extra step for pipe installation and no need to drill a new bore.

A service that CTC has always offered, it has not been a main focus of the business…until now that is!

With 197 000km of reticulation system in South Africa, the majority of which was built 30-60 years ago, ageing infrastructure and its impact on service delivery and new development is a major issue.

It is estimated that our losses on all these systems sit at about 37%, with the majority of this loss experienced in urban and peri-urban areas where trenching is difficult to implement. This of course makes it the perfect environment for trench-less services such as pipe cracking in that disruption is kept to a minimum and the safety of pedestrians is a key benefit.

Along the same vein, storm water systems face the same ageing issue having exceeded their design life and subsequently collapsing. These need to be re-sleeved or made larger or completely replaced. Again the right environment for trench-less construction.

Environmental protection is another area of demand, where less invasive alternatives to trenching are becoming a baseline requirement of many construction and civil engineering projects.

With these pressing needs, CTC has expanded its offering in this space through investment in new machines, staff resources, skills development, and coverage that allows it to undertake mega pipe cracking projects.